From "From People-to-Goods to Goods-to-Person": Intelligent Welding Material Warehouse Boosts Storage Efficiency

Release Date:

2025-04-10 08:41

Source:

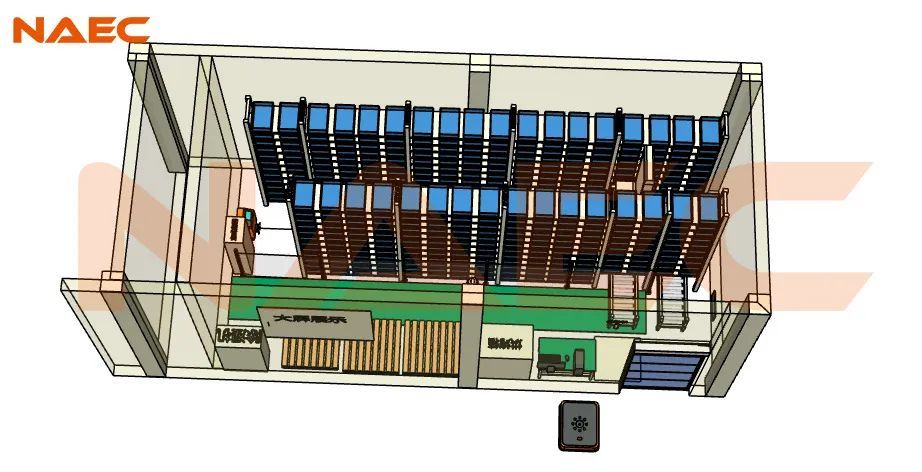

Intelligent Welding Materials Warehouse Solution

In the welding industry, the storage and management of welding materials play a critical role in the production chain. Traditional warehouse management methods often suffer from low efficiency and high error rates, making them unsuitable for modern production demands. Today, we introduce NAEC’s Intelligent Welding Material AS/RS Solution, designed to help enterprises establish an efficient and intelligent production management system—achieving cost reduction and efficiency enhancement!

Challenges in Welding Material Management

✅ High manual dependency: Inbound and outbound processes rely on manual recording, leading to frequent errors and low efficiency.

✅ Quality control challenges: Difficult to track welding material batches and drying status, making it hard to detect quality risks.

✅Inefficient inventory management: No real-time visibility into inventory levels, resulting in high risks of shortages or overstocking.

✅ Severe data silos: Disconnection from production systems (SAP/MES) causing low collaboration efficiency

NO.1

NAEC Intelligent Welding Material Warehouse

Project Planning Overview

NAEC's intelligent welding material storage system designed for a leading manufacturer achieves centralized storage of various welding consumables including coil wires, welding rod, drum fluxes, and long wires—in material bins. This system not only meets the company’s demand for intensive material storage but also enables end-to-end intelligent management—from inbound, storage, outbound, to return—by integrating intelligent warehouse management and dispatching systems.

NO.2

NAEC Intelligent Welding Material Warehouse

Core Value Proposition

Dual-Crane Collaborative Stacker System

· Dual-Crane Collaborative Operation: Two stacker cranes are deployed within a single aisle, enabling simultaneous access to multiple storage locations (≥5), effectively doubling operational efficiency.

· Three-Dimensional Motion: Horizontal movement + vertical lifting + fork extension, enabling precise access to high-bay racking and increasing space utilization by 60%;

· Intelligent Speed Control: Adjustable speeds for movement, lifting, and forks to accommodate different material types for flexible operations;

· Flexible control modes: Supports online automation (WMS commands), standalone automation (local tasks), and manual control (debugging/maintenance), adapting seamlessly to diverse operational scenarios.

Unmanned Operation Throughout the Entire Process

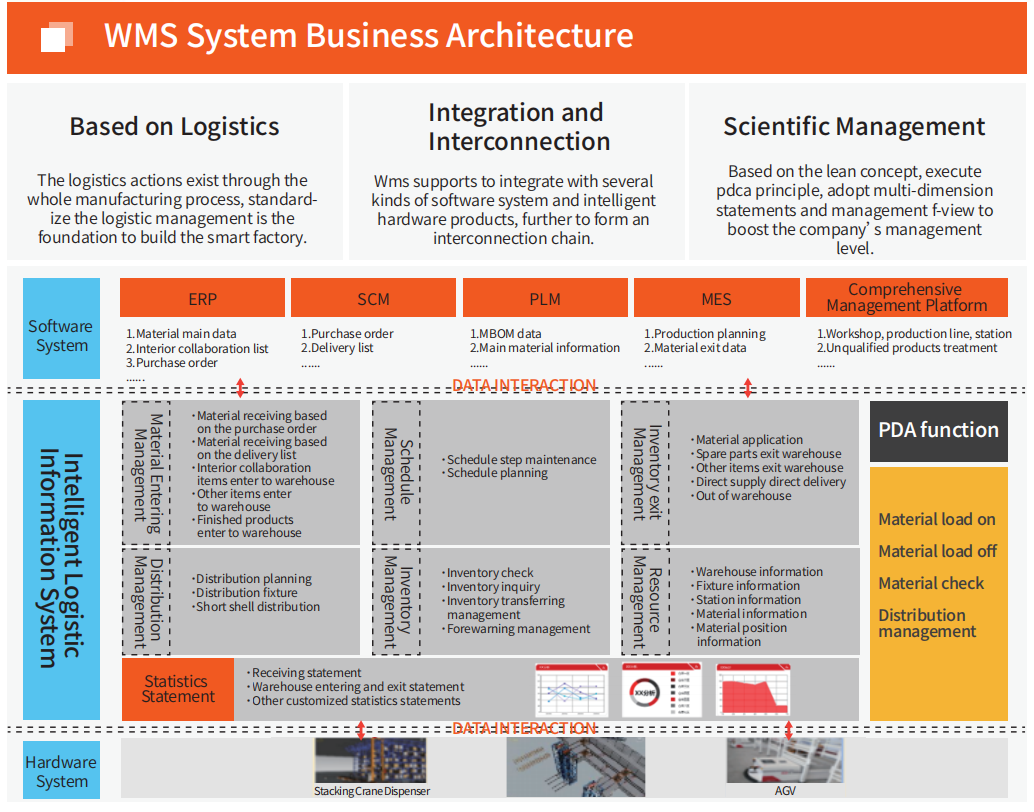

· "Unmanned" Inbound Process: From receiving instructions via SAP/MES → WMS automatically assigns storage locations → WCS schedules stacker cranes and conveyor lines → Barcode scanning, binding, and automatic weighing are performed. Through seamless integration of dual-aisle multi-position stacker cranes, laser-guided AGVs, and intelligent conveyor systems, operational efficiency is significantly improved without the need for human intervention.

·Instant Outbound Response :Real-time dispatch:Post facial/card authentication, the system schedules precise material delivery to pickup ports, with real-time information displayed on large screens, eliminating queuing delays.

·One-Click Completion" Return Process: Automatic scanning of material codes and weighing records, along with automatic return of empty bins to storage. Data is synchronized with the production system, ensuring closed-loop management with zero gaps.

Triple Precision Verification, Zero Quality Risk

• One Code Per Item Traceability: Each box of welding materials is bound with a unique QR code, recording critical information such as batch number, steel stamp number, and project number. Scanning the QR code allows for querying the full lifecycle data of the item.

•Intelligent Drying to Prevent Degradation: Welding rods and fluxes automatically enter the drying oven, with PDA (Personal Digital Assistant) used to bind the oven information, ensuring compliance with processing standards.

• Weight Inspection to Prevent Deviations: Both inbound and return processes undergo dynamic weighing. The system automatically compares the actual weight against theoretical values, triggering real-time alerts for any discrepancies.

Data-Driven Precision Management

• Seamless Integration with Enterprise Systems: Real-time data exchange with SAP/MES allows production plans to directly drive warehouse operations, with inventory dynamics visible to management;

• Visual Reports for Smarter Decisions: Automatically generates reports on inbound/outbound activity, inventory turnover, and material picking trends—supporting optimized procurement and production scheduling.

The intelligent welding material warehouse is becoming an indispensable part of modern industrial production. NAEC’s solution, through its efficient process design, advanced hardware systems, and powerful smart management platform, not only enhances productivity and reduces labor costs and error rates, but also plays a vital role in promoting intelligent industrial transformation.

Related News

Email: info@autowelds.com

Address: 11th floor, Building B4, Jiulong Lake International Enterprise Headquarters Park, No. 19 Suyuan Avenue, Jiangning District, Nanjing City, Jiangsu Province

aote

Auto Group Official Account

Auto Group Video Account

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.