Design and Application of Automated Storage and Retrieval System (AS/RS) Warehouses

Release Date:

2025-07-10 20:20

Source:

-NAEC Intelligent Logistics -

NAEC

Pain Points of Traditional Warehousing:

The Dual Dilemma of Space and Efficiency

Step into the warehouse of a traditional manufacturing enterprise and the issues are clear at a glance: piles of goods stacked haphazardly on the floor, workers navigating narrow aisles while struggling to locate materials, delayed inventory updates, and frequent discrepancies during stocktaking. More distressingly, vast overhead space remains underutilized for years while businesses bear the burden of high rental costs to expand floor space.

As "high-mix, low-volume" production becomes the norm, the inefficiencies and space wastage of traditional warehousing have become major bottlenecks to enterprise growth. Automated Storage and Retrieval Systems (AS/RS) are emerging as intelligent hubs that not only solve these problems but also empower enterprises to reduce land use, ease labor intensity, minimize storage and transportation losses, lower capital tied up in inventory, and significantly improve logistics efficiency.

NAEC

A Three-Dimensional Revolution

Core Breakthroughs of AS/RS

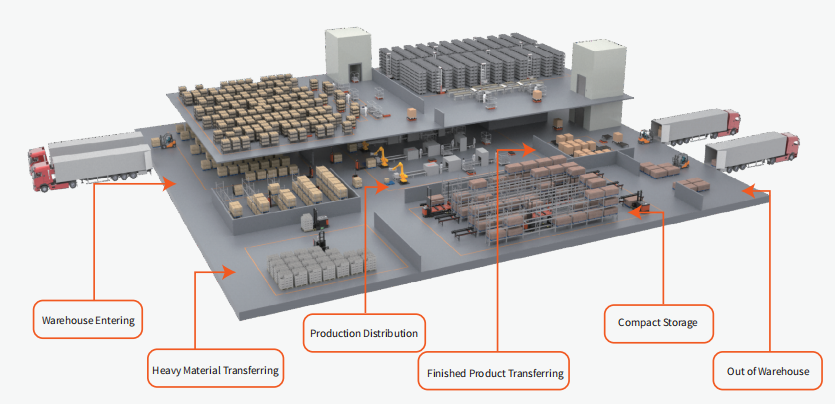

NAEC's AS/RS adopts an innovative architecture of "three-dimensional space optimization + automated equipment integration + closed-loop digital management" to help enterprises enhance warehouse management efficiency and accuracy while achieving comprehensive cost reduction and productivity improvement.

a.Space Reconstruction: Maximizing Vertical Space Utilization

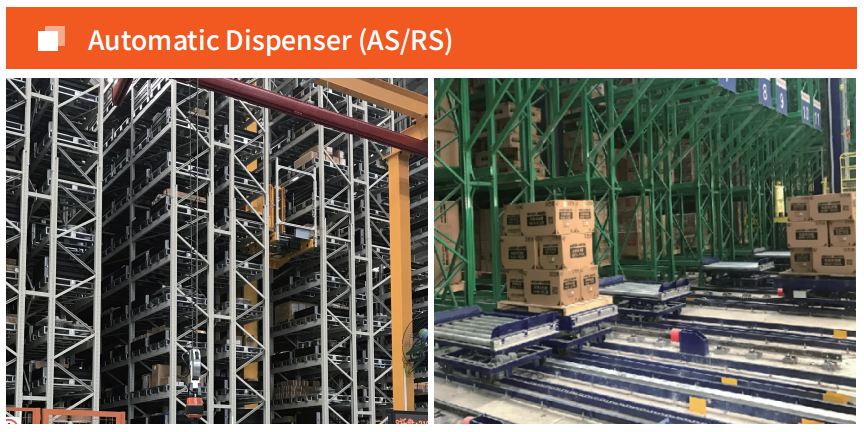

The greatest breakthrough of intelligent AS/RS lies in the effective use of vertical space. Through aisle-style racking systems, previously unused overhead areas are transformed into valuable storage zones. Modular racks allow flexible layer height adjustments, offering customized storage solutions for everything from small electronic components to large molds. Industry applications have proven that after implementation, land costs are significantly reduced and storage capacity far exceeds that of conventional warehouses for the same footprint.

b.Intelligent Operation: The New Paradigm of "Goods-to-Person"

In advanced AS/RS, various types of Stacker Cranes (such as Single-Column Servo, Heavy-Duty Double-Column, and Oversized Multi-Column) act as agile and precise executors, swiftly navigating dense racks. They, together with high-speed conveying systems, form the core of automated operations, realizing the shift from "person-to-goods" to "goods-to-person."

When a production order is issued, the system automatically triggers the entire process of location retrieval, path planning, and goods delivery. Measured data indicates significant improvements in high-frequency material picking efficiency and a notable reduction in mis-picking rates.

c.Digital Closed Loop: The Intelligent Upgrade of the Warehouse Brain

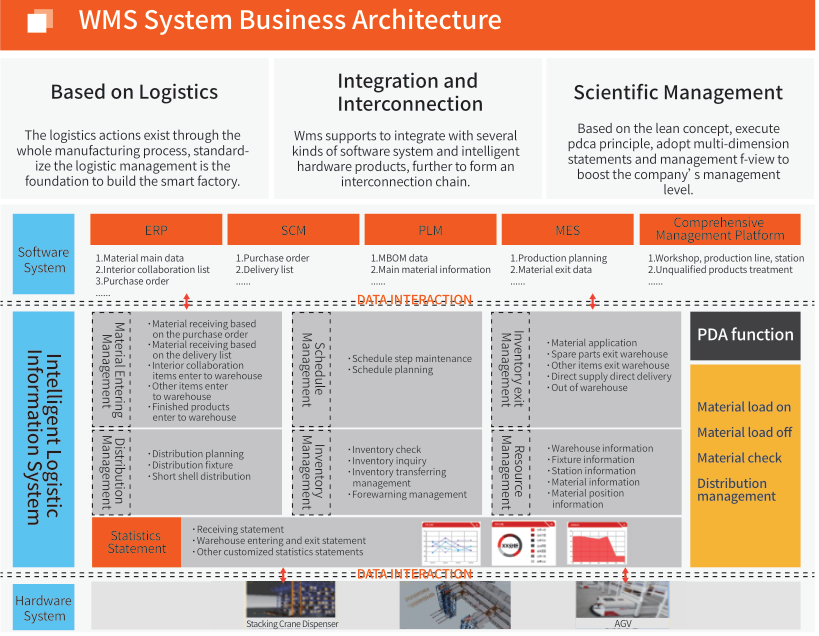

With the WMS (Warehouse Management System) at its core, NAEC builds a digital management ecosystem covering inbound/outbound processes, inventory, data, and task management. The LES (Logistics Execution System) focuses on order preprocessing, logistics execution, line-side management, container handling, while the LCS (Logistics Control System) governs routing strategies, equipment control, and monitoring.

These systems enable real-time inventory tracking, automatic generation of stocktaking reports, and proactive alerts when inventory falls below safety thresholds. More importantly, seamless integration with ERP, MES, and other core enterprise systems ensures real-time coordination of order data, warehouse operations, and production delivery.

NAEC

Industry Customization

Targeted Solutions for Specialized Requirements

The appeal of AS/RS lies in its strong adaptability, offering innovative solutions tailored to the specific pain points of different industries:

NAEC

Storage of Heavy/Irregular Items

Innovatively designed inclined-storage solutions using multi-layer adjustable racks and specialized support structures mitigate the risk of toppling and prevent deformation caused by pressure during traditional stacking.

NAEC

High Turnover Requirements

By deploying multiple inbound/outbound mechanisms, goods can be stored without the need for manual direction adjustment, significantly improving inbound efficiency.

NAEC

Rapid Deployment Requirements

The rise of standardized modular AS/RS systems addresses the long lead times and high costs of traditional customized projects. With factory-prefabricated components and fast on-site assembly and commissioning, both delivery time and overall costs are significantly reduced.

As technological costs continue to fall and solutions become more refined, AS/RS is entering a phase of rapid growth. Enterprises that proactively embrace this transformation are turning their warehouses from cost centers into engines of growth.NAEC Intelligent Logistics continues to deliver professional logistics solutions to diverse industries through reliable operational systems, scientific resource integration, and advanced management technologies.

Related News

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards

Currently, China’s shipbuilding industry is at a critical stage of intelligent transformation, yet it faces significant challenges such as uneven automation levels, fragmented information systems, and insufficient 3D digital process design capabilities, which severely hinder high-quality development. To address these issues, NAEC has launched a comprehensive intelligent shipbuilding solution that deeply integrates advanced technologies, covering the entire process from planning and design to production and quality inspection. This solution eliminates “breakpoints” and “bottlenecks” in the manufacturing chain, enabling full-chain, full-cycle digital reconstruction and intelligent upgrading of shipbuilding processes.

How to Maintain Your Heat Treatment Workstation for Longevity and Efficiency

How to Maintain Your Heat Treatment Workstation for Longevity and Efficiency Table of Contents 1. Introduction to Heat Treatment Workstations 2. Importance of Maintaining Your Heat Treatment Workstation 3. Key Maintenance Tips for Heat Treatment Workstations 3.1 Conducting Regular Inspections 3.2 Establishing Cleaning Schedules 3.3 Performing Calibration Checks

Optimal Bevel Cutting Machines for Pipeline Applications

In the industrial sector, particularly within welding and cutting equipment, bevel cutting machines play a pivotal role, especially when dealing with pipelines. These machines are engineered to create specific bevel angles on the edges of pipes, which is crucial for ensuring optimal weld quality and structural integrity. Understanding the functionality and advantages of bevel cutting machines can

Leveraging Bevel Cutting Systems for Complex Pipe Projects: Unlocking Precision and Efficiency

Leveraging Bevel Cutting Systems for Complex Pipe Projects Introduction In the realm of industrial equipment and components, particularly in the welding and cutting sector, the demand for precision and efficiency is at an all-time high. Complex pipe projects often present unique challenges that require innovative solutions. One such solution is the **bevel cutting system**. These advanced systems

Essential Insights on Preheating and Post Weld Heat Treatment in Welding Processes

Preheating and post weld heat treatment (PWHT) are two critical steps in the welding process that significantly impact the mechanical properties of welded joints. These techniques help in minimizing residual stresses, controlling thermal distortion, and achieving desired metallurgical characteristics in the welded materials. **Preheating** refers to the process of heating the base material before

Bevel cutting machine for pipeline company

Nanjing Auto: Leading Bevel cutting machine for pipeline company, providing precision cutting solutions for global pipeline projects. Our advanced Bevel cutting machine for pipeline ensures perfect weld preparation and operational efficiency

Email: info@autowelds.com

Address: 11th floor, Building B4, Jiulong Lake International Enterprise Headquarters Park, No. 19 Suyuan Avenue, Jiangning District, Nanjing City, Jiangsu Province

aote

Auto Group Official Account

Auto Group Video Account

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.