Core of Intelligent Warehousing丨WCS Functions and Process Analysis

Release Date:

2025-08-04 18:23

Source:

NAEC Intelligent Logistics

In modern intelligent warehousing and logistics systems, the Warehouse Control System (WCS) plays a pivotal role. Acting as the "brain" of the warehouse, it orchestrates various devices and operational workflows to ensure efficient and precise warehouse operations.

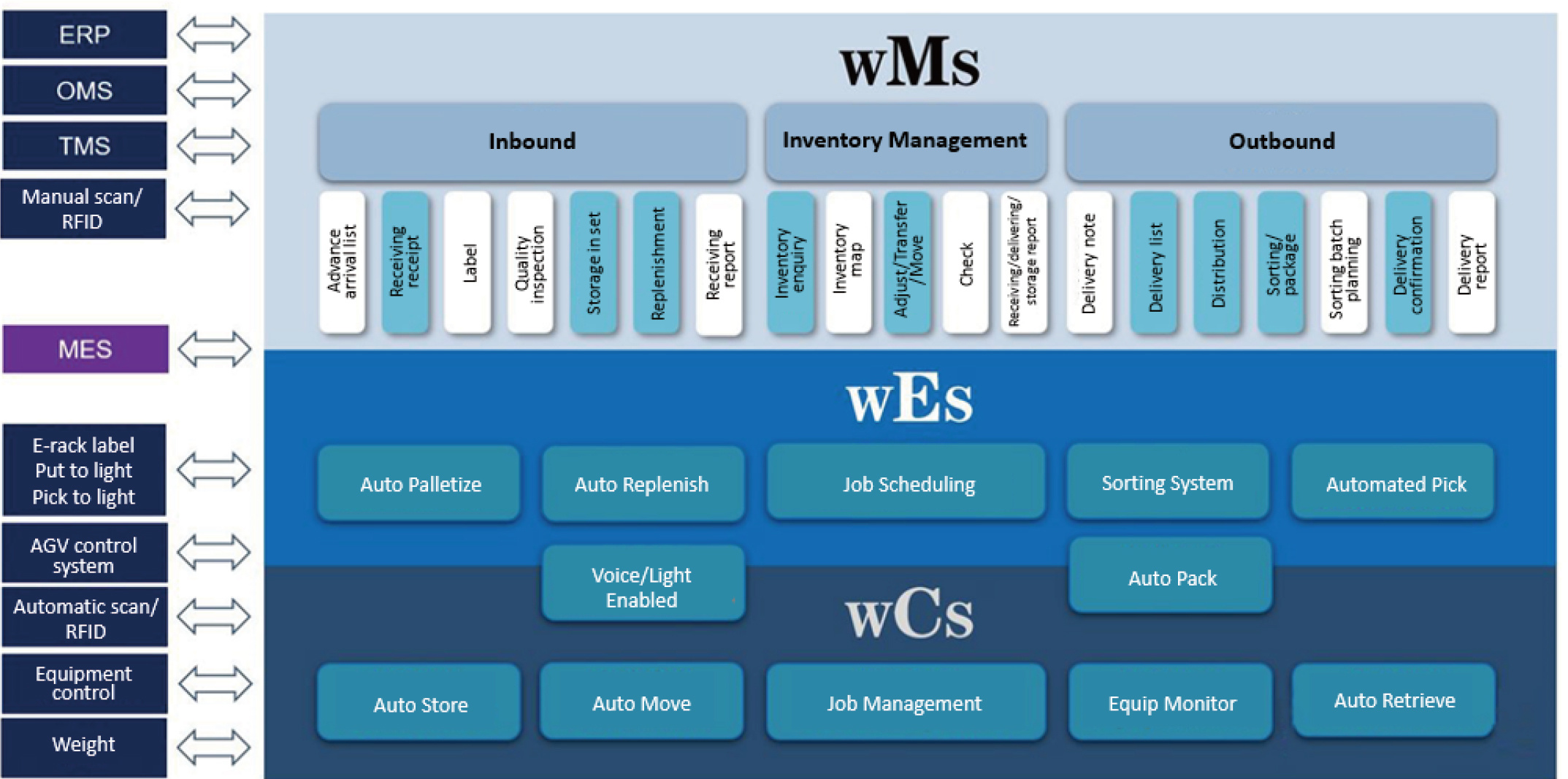

WCS, or Warehouse Control System, is positioned between the Warehouse Management System (WMS) and the Programmable Logic Controllers (PLCs) in the three-layer architecture of intelligent warehousing. It serves as a critical middleware that receives operational instructions from the WMS, translates them into executable commands for PLCs, and provides real-time monitoring and feedback on equipment status back to the WMS.

01 Core Functions of WCS

01 Integration with Internal Warehouse Systems

WCS frequently interfaces with major enterprise management software such as WMS and ERP systems. Positioned at the execution layer within the enterprise information flow, WCS obtains instructions from upper-level systems to guide warehouse operations.

02 Seamless Integration with On-Site Automation Equipment

WCS does not interface directly with hardware but communicates through protocols with the PLCs that control physical devices—managing movements such as advancing or retracting.

03 Real-Time Warehouse Monitoring & Equipment Status Feedback

WCS serves as the on-site warehouse monitor, providing accurate visibility into the status, location, alarm conditions, and task execution of all hardware equipment within the AS/RS(Automated Storage and Retrieval System). Its built-in 3D monitoring system offers an intuitive display of warehouse operations to managers.

04 WCS Safety Functions

For unmanned warehouses, safety assurance is paramount alongside operational efficiency. WCS must incorporate comprehensive safety design considerations, including equipment safety, cargo protection, collision avoidance mechanisms, path planning, and overall enhancement of AS/RS safety standards.

02 Key WCS Processes

Inbound Process

Receive Task:

Receives complete inbound instructions from the WMS, including item types, quantities, specifications, and preassigned storage locations.

Goods Transfer:

Once goods arrive at the receiving area, the conveyor system automatically transports them. During transit, barcode or RFID scanning verifies information. In case of damage or data mismatch, the system diverts the goods to an exception-handling zone.

Execute Operation:

WCS dispatches the optimal stacker crane (based on real-time status like position/load) to retrieve goods from the conveyor and deliver them to the designated location via the most efficient path.

Confirm & Feedback:

Upon successful storage, WCS sends feedback to the WMS, including storage location and timestamp. This allows WMS to update inventory records in real time.

Outbound Process

Receive Task: Receives outbound instructions from the WMS specifying item types, quantities, and designated outbound locations.

Goods Retrieval:WCS dispatches stackers to the appropriate locations based on item codes. The goods are retrieved and transferred to the outbound conveyors.

Sorting and Transport:Goods are moved via conveyors to the sorting area. Based on the WMS instructions, WCS directs sorting equipment (e.g., cross-belt sorters) to channel items to their designated outbound conveyors.

Outbound Confirmation:A second verification is performed at the outbound station. Once confirmed, the goods are released for dispatch, and WCS provides outbound status updates to the WMS for inventory deduction.

Inventory Counting Process

Receive Task: Receives inventory check instructions from the WMS, detailing the scope—whether a full warehouse check or a targeted audit of specific areas or product categories.

Device Scanning:WCS coordinates stackers, AGVs, and other devices to follow an optimized path, reaching each storage location to scan item and location data in real time.

Data Comparison:The collected data is automatically compared with WMS inventory records. Any discrepancies in quantity or classification are flagged, and a detailed variance report is generated.

Result Feedback:The inventory results and discrepancy report are synchronized with the WMS to assist warehouse personnel in verification. After reconciliation, the WMS updates inventory data to ensure record accuracy.

·

03 Applications of WCS Across Various Industries

NAEC

About

E-Commerce Industry

In large-scale e-commerce warehouses, where order volumes fluctuate heavily, WCS enables rapid response to dynamic inbound and outbound tasks. Through efficient equipment scheduling and task assignment, it ensures fast sorting and fulfillment, boosting customer satisfaction.

NAEC

About

Pharmaceutical Industry

Pharmaceutical warehouses demand strict environmental control and inventory accuracy. WCS not only manages parameters such as temperature and humidity but also ensures FIFO compliance and precise batch control. Integrated with traceability systems, it ensures full lifecycle tracking of pharmaceutical products.

NAEC

About

Manufacturing Industry

In raw material and finished goods warehouses of manufacturing enterprises, WCS is tightly integrated with production management systems. It delivers raw materials to production lines according to schedules and efficiently stores finished products. For instance, in automotive manufacturing, WCS can coordinate AGVs to deliver components accurately to assembly lines, enhancing productivity and reducing operational costs.

As the invisible nerve center of modern intelligent warehousing, the efficient operation of WCS directly determines the efficiency and reliability of logistics. Auto Intelligence Logistics' automated warehousing systems have been deployed across manufacturing, petrochemicals, 3C electronics, and numerous other industries. We provide professional logistics services through reliable operational systems, scientific resource integration, and advanced management technologies.

Related News

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards

Currently, China’s shipbuilding industry is at a critical stage of intelligent transformation, yet it faces significant challenges such as uneven automation levels, fragmented information systems, and insufficient 3D digital process design capabilities, which severely hinder high-quality development. To address these issues, NAEC has launched a comprehensive intelligent shipbuilding solution that deeply integrates advanced technologies, covering the entire process from planning and design to production and quality inspection. This solution eliminates “breakpoints” and “bottlenecks” in the manufacturing chain, enabling full-chain, full-cycle digital reconstruction and intelligent upgrading of shipbuilding processes.

How to Maintain Your Heat Treatment Workstation for Longevity and Efficiency

How to Maintain Your Heat Treatment Workstation for Longevity and Efficiency Table of Contents 1. Introduction to Heat Treatment Workstations 2. Importance of Maintaining Your Heat Treatment Workstation 3. Key Maintenance Tips for Heat Treatment Workstations 3.1 Conducting Regular Inspections 3.2 Establishing Cleaning Schedules 3.3 Performing Calibration Checks

Optimal Bevel Cutting Machines for Pipeline Applications

In the industrial sector, particularly within welding and cutting equipment, bevel cutting machines play a pivotal role, especially when dealing with pipelines. These machines are engineered to create specific bevel angles on the edges of pipes, which is crucial for ensuring optimal weld quality and structural integrity. Understanding the functionality and advantages of bevel cutting machines can

Leveraging Bevel Cutting Systems for Complex Pipe Projects: Unlocking Precision and Efficiency

Leveraging Bevel Cutting Systems for Complex Pipe Projects Introduction In the realm of industrial equipment and components, particularly in the welding and cutting sector, the demand for precision and efficiency is at an all-time high. Complex pipe projects often present unique challenges that require innovative solutions. One such solution is the **bevel cutting system**. These advanced systems

Essential Insights on Preheating and Post Weld Heat Treatment in Welding Processes

Preheating and post weld heat treatment (PWHT) are two critical steps in the welding process that significantly impact the mechanical properties of welded joints. These techniques help in minimizing residual stresses, controlling thermal distortion, and achieving desired metallurgical characteristics in the welded materials. **Preheating** refers to the process of heating the base material before

Bevel cutting machine for pipeline company

Nanjing Auto: Leading Bevel cutting machine for pipeline company, providing precision cutting solutions for global pipeline projects. Our advanced Bevel cutting machine for pipeline ensures perfect weld preparation and operational efficiency