Fully Automated End-to-End Solution丨Hydraulic Cylinder Welding Workstation

Release Date:

2025-05-20 00:00

Source:

NAEC

In the wave of global intelligent manufacturing, efficient, precise, and flexible automated production equipment has become the core driving force for industrial transformation and upgrading. Addressing the challenges of complex welding processes, diverse specifications, and strict quality requirements in the hydraulic cylinder industry, NAEC has developed a new-generation Hydraulic Cylinder Welding Workstation. This workstation redefines welding productivity through a fully automated solution.

Overview

NAEC

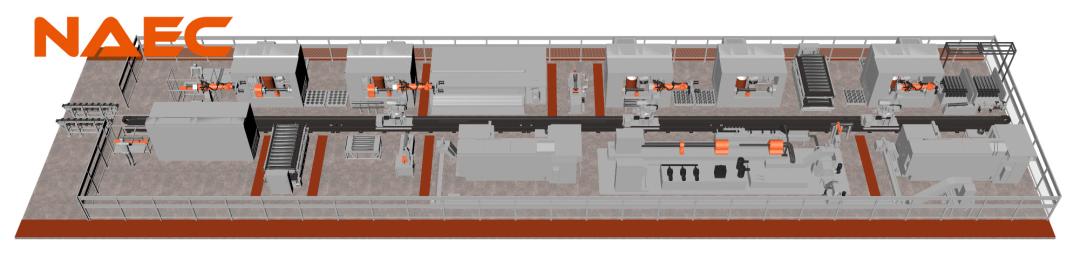

Flexible Intelligent Manufacturing System丨Resolving Multi-Spec Production Challenges

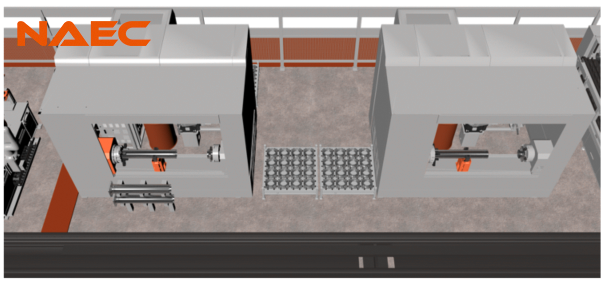

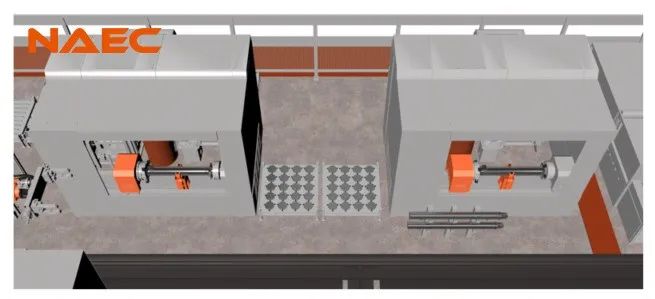

NAEC's Hydraulic Cylinder Welding Workstation adopts a modular design concept, with a streamlined logistics layout that integrates AGV logistics systems, material-handling robots, and intelligent slat conveyors. Together, they form a complete closed-loop process from material transport to final inspection.

Highlights

NAEC

Core Process Innovation – The Choice for Efficient Welding

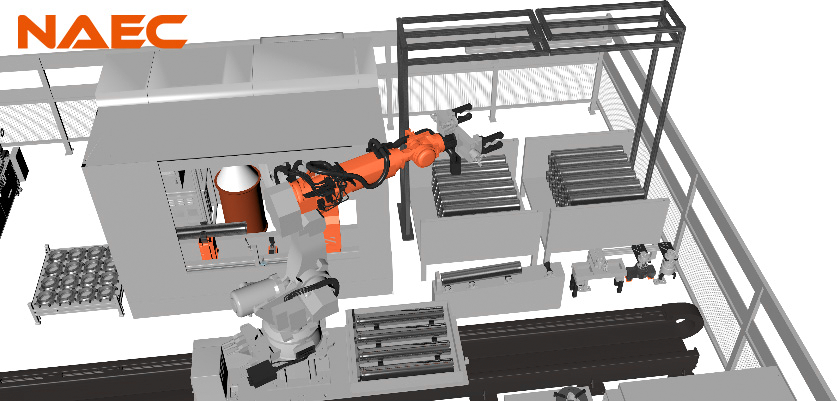

Cylinder Loading Area

The handling robot system achieves efficient and accurate material handling and process assistance through multi-dimensional configuration and technological application. In the automatic material pickup stage, the 3D vision-based disordered picking function enables the robot to flexibly handle various complex stacking scenarios, quickly and accurately grasping materials.

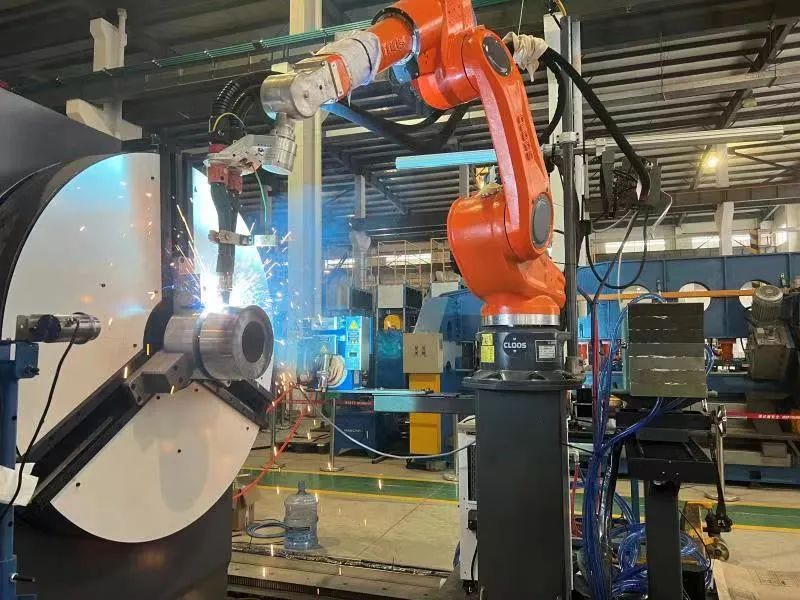

Flange & Port Assembly Welding Area

In terms of full-process automation, the system covers key stages such as automatic loading/unloading, automatic positioning and clamping, flange automatic fitting, and robotic automatic tack welding. The integrated laser seam tracking system automatically and precisely locates the angular position of oil ports,effectively ensuring high precision and stability during automatic flange assembly.

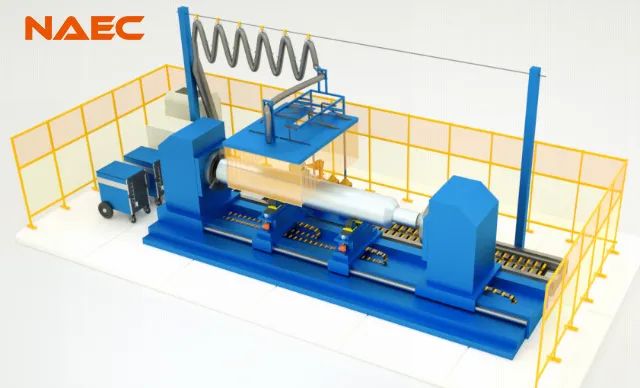

Cylinder Bottom Valve Seat Welding Area

This automated system emphasizes high integration and intelligence, building an efficient operational structure that spans the entire process. It includes automatic loading/unloading, positioning and clamping, preheating, and robotic tack welding to ensure continuous and efficient production. The laser tracking system accurately detects oil port angles, providing reliable technical support for automated assembly and significantly enhancing precision and efficiency.

Automatic Inspection

Automatic Inspection

The measurement system achieves integrated thread and contour measurement, greatly improving measurement accuracy, convenience, and safety through technical innovation and function optimization.

In terms of equipment protection and measurement accuracy control, the system is equipped with comprehensive protective mechanisms for all moving axes, extending the service life of the equipment. At the same time, intelligent constant contact force technology minimizes measurement errors caused by changes in contact force, achieving high-precision measurement for both soft and hard workpieces.

In the era of intelligent transformation in manufacturing, NAEC's hydraulic cylinder welding workstation, with its forward-looking technological strategy and innovative practices, not only deeply integrates flexible manufacturing with core process innovation but also provides a one-stop solution for hydraulic cylinder welding production that combines efficiency and quality through end-to-end automation and precision inspection systems, continuously empowering high-quality development in the manufacturing industry.

Related News

Email: info@autowelds.com

Address: 11th floor, Building B4, Jiulong Lake International Enterprise Headquarters Park, No. 19 Suyuan Avenue, Jiangning District, Nanjing City, Jiangsu Province

aote

Auto Group Official Account

Auto Group Video Account

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.