Innovation Breakthrough! NAEC Builds High-Efficiency Lean Pipe Spool Fabrication Production Line for Nuclear Power Project

Release Date:

2025-08-28 00:00

Source:

In nuclear power construction, enhancing the intelligence and efficiency of the pipe spool fabrication process is of paramount importance. With nearly 30 years of industry service experience and proven capabilities in implementing intelligent construction solutions, NAEC has developed a tailored lean manufacturing solution for the pipe spool fabrication production line of a major domestic nuclear power company, following in-depth research and evaluation.

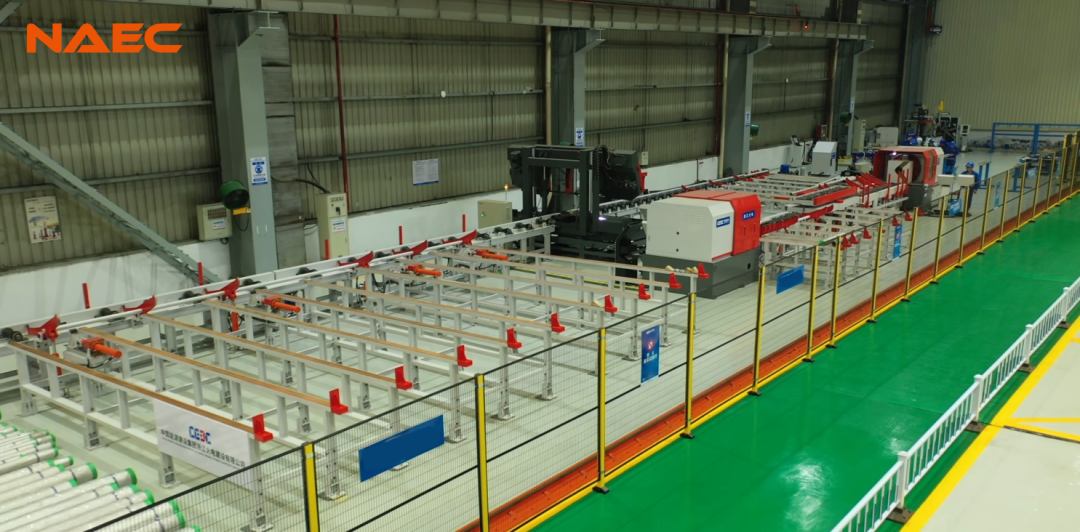

Through its self-developed production line control system and intelligent gantry coordination, NAEC has achieved fully unmanned operation in the cutting area of the 2–8 inch carbon steel/stainless steel pipe spool fabrication production line. The intelligent logistics system delivers materials precisely to designated workstations, ensuring smooth and efficient production flow.

NAEC

01 Scientific Line Layout: Demand-Oriented, Optimized Efficiency

The planned fully digitalized intelligent production line covers raw material buffering, cutting, beveling, grinding, automatic fit-up, and intelligent logistics. The overall layout is streamlined, transportation is efficient, and production continuity and stability are fully guaranteed.

NAEC

02 Intelligent Control Hub: Flexible, Efficient, Cost-Reducing

The line is equipped with a centralized control workstation, allowing both independent station operation and system interconnection. Production tasks can be flexibly assigned through MES system automation or Excel import, enabling labeling, cutting, beveling, and grinding tasks to be dispatched with ease—boosting productivity while reducing material cost and waste.

NAEC

03 Core Process Equipment: Precision, Stability, Reliability

Equipped with circular saws, beveling machines, grinding stations, integrated fit-up, and integrated welding stations, the line ensures high-quality processing with low material loss. Easy to install and operate, it delivers over 40% improvement in single-pipe operation efficiency.

NAEC

04 Safety and Reliability with Continuous Upgradability

The equipment is safe and reliable, with core electrical components sourced from globally renowned brands such as Siemens and Inovance, ensuring stability and durability. Designed for long-duration high-efficiency operation (target: 1,000+ hours without failure), the line also features expandable interfaces and modular upgrades, laying a solid foundation for future functionality enhancements.

The high-efficiency lean pipe spool fabrication production line developed by NAEC Group for nuclear power projects has achieved fully unmanned operations and scientific planning, providing strong support for the long-term development of the production line. This breakthrough has significantly improved efficiency, reduced costs, and enhanced quality.

Related News

NAEC Intelligent Shipbuilding Solutions for Smart Shipyards

Currently, China’s shipbuilding industry is at a critical stage of intelligent transformation, yet it faces significant challenges such as uneven automation levels, fragmented information systems, and insufficient 3D digital process design capabilities, which severely hinder high-quality development. To address these issues, NAEC has launched a comprehensive intelligent shipbuilding solution that deeply integrates advanced technologies, covering the entire process from planning and design to production and quality inspection. This solution eliminates “breakpoints” and “bottlenecks” in the manufacturing chain, enabling full-chain, full-cycle digital reconstruction and intelligent upgrading of shipbuilding processes.

How to Maintain Your Heat Treatment Workstation for Longevity and Efficiency

How to Maintain Your Heat Treatment Workstation for Longevity and Efficiency Table of Contents 1. Introduction to Heat Treatment Workstations 2. Importance of Maintaining Your Heat Treatment Workstation 3. Key Maintenance Tips for Heat Treatment Workstations 3.1 Conducting Regular Inspections 3.2 Establishing Cleaning Schedules 3.3 Performing Calibration Checks

Optimal Bevel Cutting Machines for Pipeline Applications

In the industrial sector, particularly within welding and cutting equipment, bevel cutting machines play a pivotal role, especially when dealing with pipelines. These machines are engineered to create specific bevel angles on the edges of pipes, which is crucial for ensuring optimal weld quality and structural integrity. Understanding the functionality and advantages of bevel cutting machines can

Leveraging Bevel Cutting Systems for Complex Pipe Projects: Unlocking Precision and Efficiency

Leveraging Bevel Cutting Systems for Complex Pipe Projects Introduction In the realm of industrial equipment and components, particularly in the welding and cutting sector, the demand for precision and efficiency is at an all-time high. Complex pipe projects often present unique challenges that require innovative solutions. One such solution is the **bevel cutting system**. These advanced systems

Essential Insights on Preheating and Post Weld Heat Treatment in Welding Processes

Preheating and post weld heat treatment (PWHT) are two critical steps in the welding process that significantly impact the mechanical properties of welded joints. These techniques help in minimizing residual stresses, controlling thermal distortion, and achieving desired metallurgical characteristics in the welded materials. **Preheating** refers to the process of heating the base material before

Bevel cutting machine for pipeline company

Nanjing Auto: Leading Bevel cutting machine for pipeline company, providing precision cutting solutions for global pipeline projects. Our advanced Bevel cutting machine for pipeline ensures perfect weld preparation and operational efficiency

Email: info@autowelds.com

Address: 11th floor, Building B4, Jiulong Lake International Enterprise Headquarters Park, No. 19 Suyuan Avenue, Jiangning District, Nanjing City, Jiangsu Province

aote

Auto Group Official Account

Auto Group Video Account

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.