Application of Automated Storage and Retrieval Systems (AS/RS) in Silicon Steel Coil Workshops

Release Date:

2025-06-20 12:00

Source:

NAEC Intelligent Logistics

With the advent of the Industry 4.0 era, intelligent manufacturing and automation technologies have found widespread application across various industries. In silicon steel coil workshops, automated storage and retrieval systems (AS/RS), as an efficient and intelligent warehousing solution, are gradually replacing traditional manual storage methods. They have become a crucial means to enhance production efficiency, reduce costs, and optimize management processes.

PART 1

Overview of Automated Storage and Retrieval Systems (AS/RS)

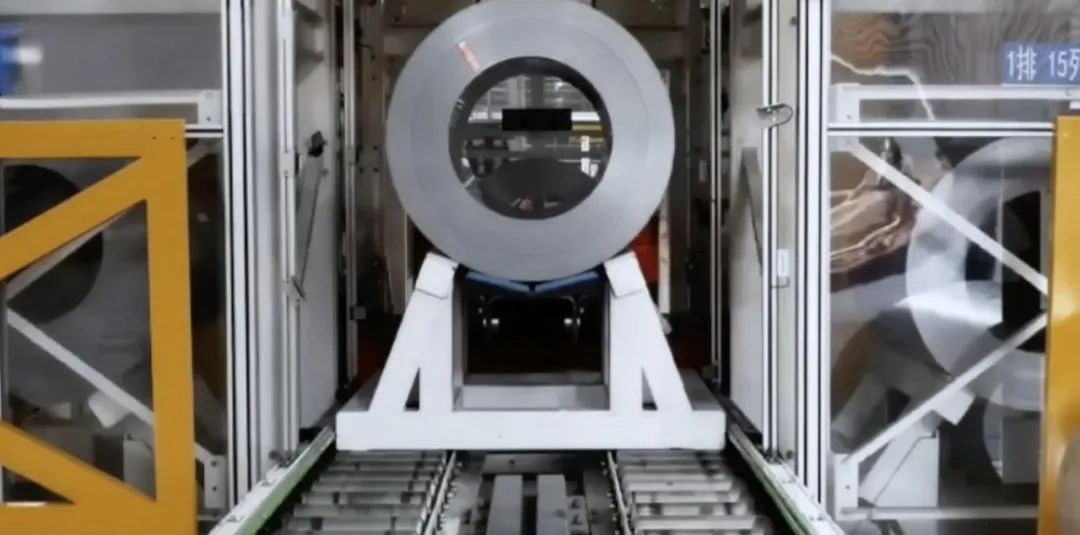

An Automated Storage and Retrieval System (AS/RS) is a modern intelligent warehousing system. It utilizes advanced equipment such as high-bay racking, stacker cranes, inbound/outbound workstations, and automated material handling systems with operational control systems to achieve rationalized vertical storage, automated access, and simplified operations. Managed through computer and barcode technology, AS/RS efficiently and accurately completes goods storage and retrieval operations, significantly improving space utilization and operational efficiency.

PART2

Application Advantages of AS/RS in Silicon Steel Coil Workshops

1.Improved Space Utilization:

Silicon steel coils are bulky and heavy, making it difficult for traditional warehouses to fully utilize space. AS/RS, through the combination of high-bay racking and stacker cranes, maximizes vertical space utilization, potentially doubling or more the storage capacity and greatly enhancing space efficiency.

2.Enhanced Operational Efficiency:

AS/RS employs stacker cranes for storage and retrieval operations, offering high speed and accuracy. In silicon steel coil workshops, this enables rapid completion of coil inbound, outbound, and transfer operations, reducing waiting times and boosting production efficiency.

3.Reduced Labor Costs:

Traditional warehouses require significant manual labor for handling, stacking, and record-keeping. AS/RS automates storage, retrieval, and management tasks through automated equipment and computer management systems, drastically reducing labor requirements and associated costs.

4.Optimized Management Processes:

AS/RS is equipped with an advanced Warehouse Management System (WMS), which records real-time information on goods movement, inventory status, and facilitates data exchange with other systems via networks. This brings greater transparency and efficiency to management processes in silicon steel coil workshops, aiding production planning and inventory control.

PART3

Specific Applications of AS/RS in Silicon Steel Coil Workshops

01.Operation: Inbound Process

Upon arrival at the AS/RS inbound area via transport equipment, the stacker crane, guided by the WMS, automatically transports the silicon steel coil to its designated storage location and updates the system information.

02.

When coils need to be dispatched, the WMS generates outbound instructions based on production schedules or order information. The stacker crane retrieves the specified coil from its location and transports it to the outbound area.

03

Occasionally, coils need to be relocated within the workshop to optimize space utilization or meet production requirements. AS/RS facilitates this easily: relocation instructions simply need to be entered into the WMS.

The application of NAEC's Automated Storage and Retrieval Systems in silicon steel coil workshops not only enhances space utilization and operational efficiency but also reduces labor costs and optimizes management processes, thereby boosting overall enterprise competitiveness. As intelligent manufacturing and automation technologies continue to evolve, AS/RS will see broader application across more sectors, delivering greater economic and social benefits to enterprises.

Related News

Maximizing Efficiency with Integrated Cutting and Beveling Machines

Integrated cutting and beveling machines have emerged as vital components in the industrial equipment sector, particularly in welding and cutting operations. These machines streamline workflows by combining the capabilities of cutting and beveling into one compact unit, offering manufacturers significant advantages in terms of efficiency, precision, and cost-effectiveness. One of the primary benef

The Advantages of Integrated Cutting and Beveling Machines in Industrial Applications

In the realm of industrial equipment, particularly in welding and cutting applications, integrated cutting and beveling machines have emerged as vital tools for improving efficiency and accuracy. These machines are designed to perform both cutting and beveling operations in a single process, making them invaluable for various industries, including manufacturing, shipbuilding, and construction. One

Innovations in Heat Treatment Workstations: What’s New in the Industry?

Innovations in Heat Treatment Workstations: What’s New in the Industry? Table of Contents 1. Introduction to Heat Treatment Workstations 2. The Importance of Heat Treatment in Industrial Processes 3. Recent Innovations in Heat Treatment Technology 4. Advanced Equipment for Heat Treatment Workstations 5. Smart Technology Integration in Heat Treatment 6. Enhancing Energy Eff

Mastering Bevel Cutting Machines for Pipeline Applications

Bevel cutting machines play a crucial role in the pipeline industry, where precision and quality are paramount. These machines are designed to create beveled edges on pipes, facilitating better welding and assembly. Understanding the functionalities and applications of bevel cutting machines can significantly enhance operational efficiency and product quality in your projects. One of the primary a

Bevel Cutting Techniques Every Welder Should Know

Bevel Cutting Techniques Every Welder Should Know Introduction to Bevel Cutting in Welding In the realm of welding, precision is paramount. One of the critical techniques that every welder must master is bevel cutting. This process involves creating an angled edge on the metal surface, facilitating stronger joints and enhancing the overall quality of the weld. Understanding bevel cutting techniq

Understanding Preheating and Post Weld Heat Treatment in Welding Processes

In industrial welding practices, preheating and post weld heat treatment (PWHT) play vital roles in ensuring the quality and durability of welded joints. These processes are especially important when working with materials that are susceptible to cracking or distortion during and after welding. Understanding and implementing these techniques can significantly improve the outcomes of your welding p

Email: info@autowelds.com

Address: 11th floor, Building B4, Jiulong Lake International Enterprise Headquarters Park, No. 19 Suyuan Avenue, Jiangning District, Nanjing City, Jiangsu Province

aote

Auto Group Official Account

Auto Group Video Account

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.